自动化是发展的必然趋势!随着工业4.0已经在全面铺开,5G时代的到来,德国等一些西方发达国家已经提出工业5.0的构想,自动化生产将会成为一个企业的竞争核心力,因为其带来的产品标准质量化、生产成本、公司产值数据可控化,公司资金精准化等,这无疑会关系到每一个传统企业的竞争力,企业能否在激烈竞争的战场上站稳脚跟,关键看能否把握自动化变革的机遇。

天机自成立以来,持续深耕自动化行业,截止20年底,在工业领域,使用天机产品的客户已超300余家,在线稳定运行机器人5000台套,产品畅销广东、江苏、浙江、上海、福建、湖南、四川、重庆等地。

所见“机”所得

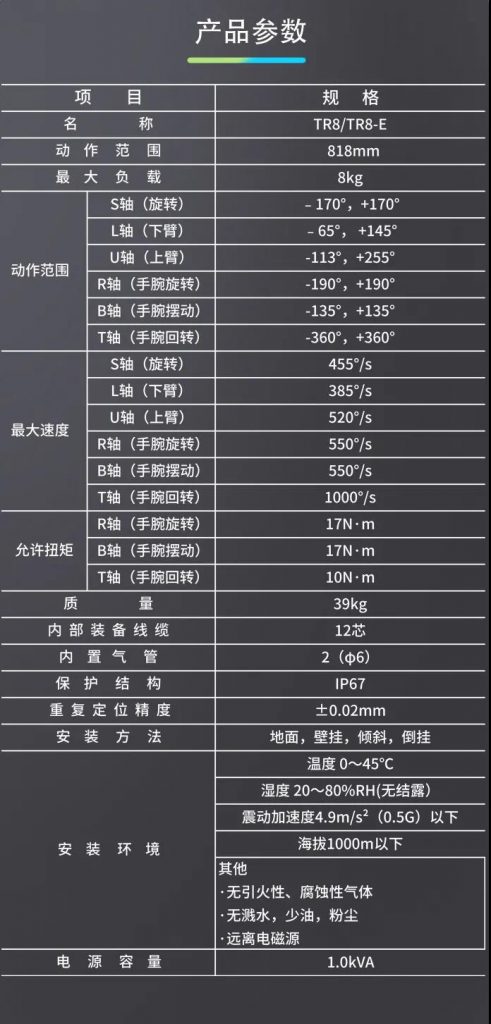

TR8负载8kg,臂长818mm,可搭载各类夹具和传感器,对应高精密组装、检测、打磨、抛光、涂胶、搬运等不同行业应用,通过高速高精密动作,减少节拍显著提高生产效率。

TR8整机防护等级IP67,即使在油雾、粉尘、潮湿、高温等恶劣环境,TR8也可从容应对!

TR8系列赋能汽车零部件、3C电子、制鞋、精密加工、商业等行业帮助客户实现智能化转型升级。

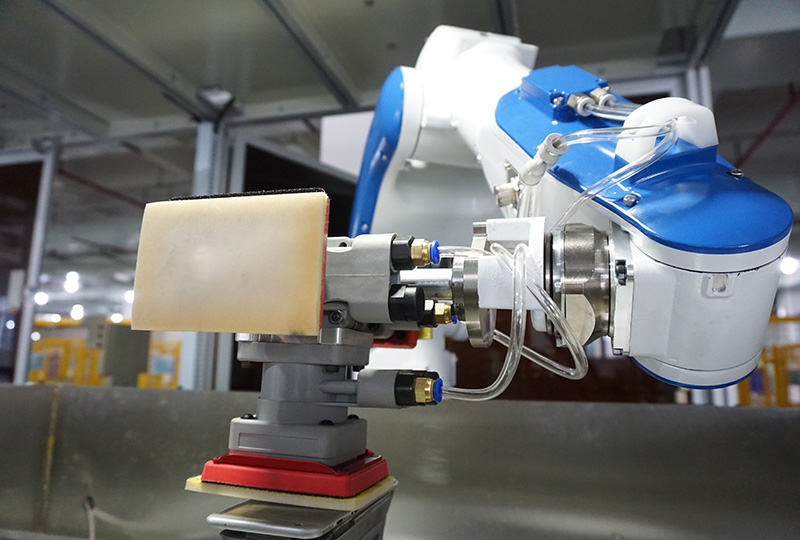

TR系列在制鞋领域的应用

鞋底动态跟随涂胶

在高速流动的传送带上,两台天机TR8机器人末端配合胶水喷枪实现动态跟随喷胶,兼容各种鞋底类型。该方案为客户解决了人工喷胶、涂胶的不均匀、缺胶、溢胶等问题,且大幅度提高生产效率,投资回报周期小于1年。

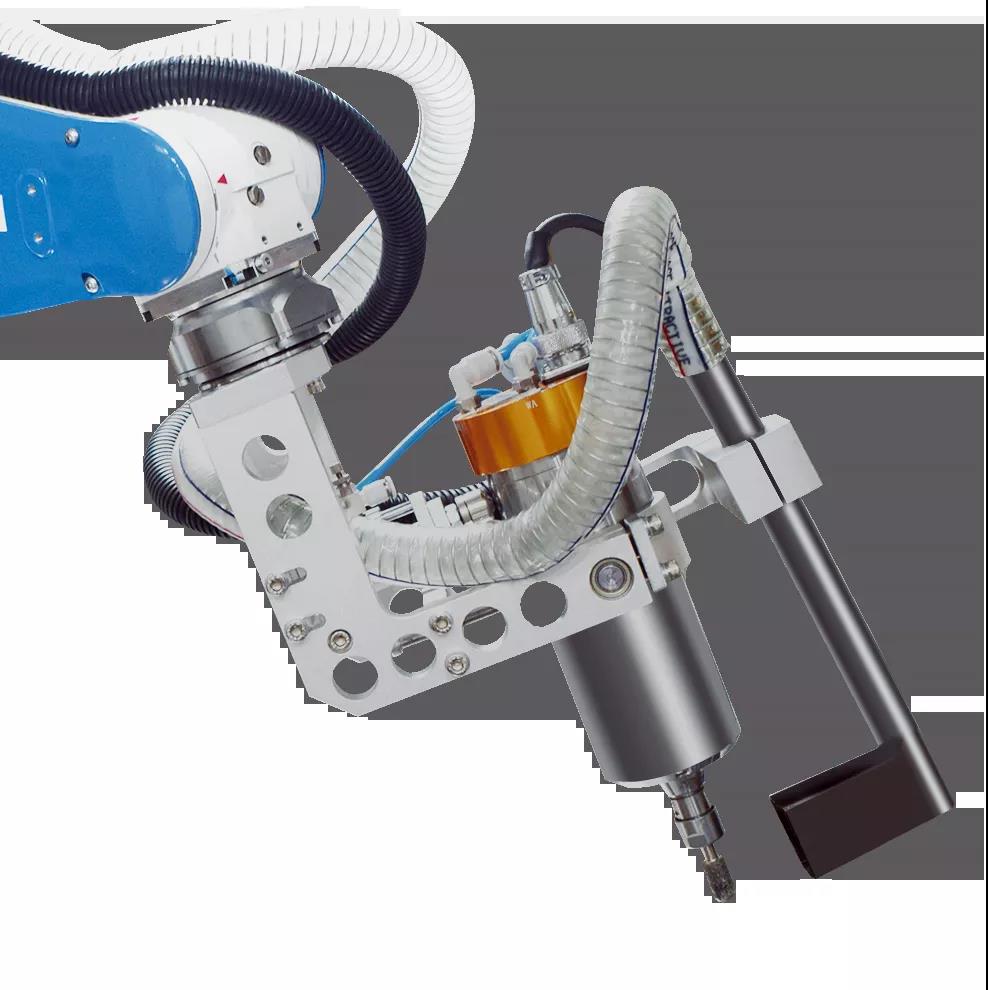

鞋帮力控打磨

▲天机力控打磨设备

▲天机浮动打磨头

一台天机TR8配合3D智能相机以及力控打磨系统,为客户实现鞋帮全自动化打磨。3D视觉识别出鞋底涂胶面,自动生成三维模型。力控打磨系统采用精度0.1N、频率100hz的六维力-力矩传感器,响应频率达250hz的六轴机器人,实时监测并反馈打磨数据,通过力控打磨系统进行打磨加工,能使系统对接触力更好的感知和反应,降低编程工作复杂度,节约工时,实现柔性自适应打磨生产。作业过程中,机器人即时高质量修正路径,从而实现对打磨力的恒定控制。

TR系列在汽车领域的应用

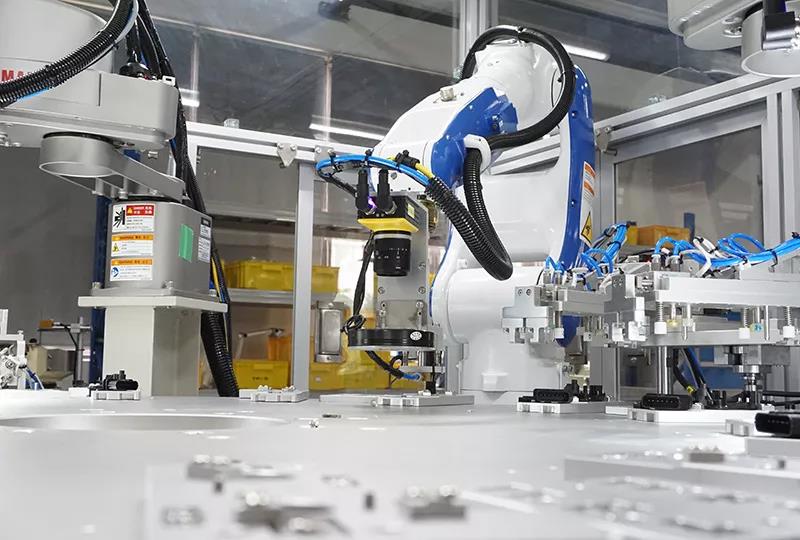

Automotive Parts Assembly This assembly line consists of 2 manual loading and unloading stations, a metal sheet assembly mechanism, and three switch assembly units forming an eight-station indexing rotary workstation. Each switch assembly station is equipped with a single CCD for positioning. A four-axis robotic arm completes the loading and assembly of the switches. With the assistance of CCD and lighting components, precise positioning is achieved. The metal sheet assembly mechanism uses the Tianji Robot TR8 for incoming material visual positioning and gripping, and assembly hole detection, completing the side assembly of metal sheets. The Tianji Robot TR8 perfectly addresses various issues related to special assembly angles and travel requirements that cannot be met, providing customers with efficient, precise, and stable service.

旋铆工位上料

该组装线上由一台天机TR8实现对旋铆工位上下料,该方案完美代替人工进行重复性的工作,节省人力至少2人,投资回报率小于1年。

TR系列在PCB行业的应用

PCB板搬运上下料该生产线由一台天机TR8对传送带上流动的PCB板进行搬运上下料,在不对产品进行损害的情况下高速运转。

TR系列在家电行业的应用

空气净化器胶塞装配 该生产线由天机TR8在流动传送带上的空气净化器产品进行胶塞装配,此项目对精度要求较高,累积误差不超过0.04mm,CT:12s/pcs,良率在90%以上。该方案为客户节省人力至少3人,大幅度提高了产品良率以及生产效率。

TR系列在3C领域的应用

CNC自动化放取料 一台天机机器人TR8对应一台或两台CNC自动上下料,性能稳定,维护简单,车间千台CNC全部由天机机器人自主上下料,CNC加工结束后无需等待,天机机器人TR8自动更换产品,大幅度提高生产效率。

TR8机器人检测

This production line is composed of various process equipment, with materials being transported via the conveyor system. TR8 robots handle the fully automated loading and unloading, achieving maximum production flexibility. The process equipment includes dimension inspection devices, appearance inspection devices, performance inspection devices, and precision assembly equipment. This line is suitable for the size and performance inspection of various precision components or casing products in the 3C industry.

机器人打磨线

Tailored to different customer processes, the Tianji Robot TR8 utilizes both single and triple grinding heads, combined with an automated double-layer logistics conveyor, and equipped with a robotic loading and unloading system, greatly enhancing the yield rate and consistency of quality. This grinding line is suitable for polishing and grinding exterior parts of various products in the 3C industry.

Cellphone Back Cover Production Standard Workstation

This workstation is composed of CNC, TR8 loading and unloading, TR8 grinding, TR8 robot automatic inspection, and auxiliary material application stations. It also utilizes smart cameras for auxiliary material inspection and employs high-speed precision linear motors for probe positioning. The entire workstation operates with three robots working in coordination, ensuring precision, efficiency, and stability, and can save the labor of 12 workers.

Dry Ice Spraying

The TR8 robot integrates dry ice deburring with conveyor line transportation, allowing for batch deburring of products. This method is more efficient, safer, and more stable than manual processes.

业务联系

电话 :0769-2292095-3115

地址:东莞市松山湖工业西三路6号3栋

邮箱:tjzn.sales@ewpt.com

官网:www.tianjirobot.com